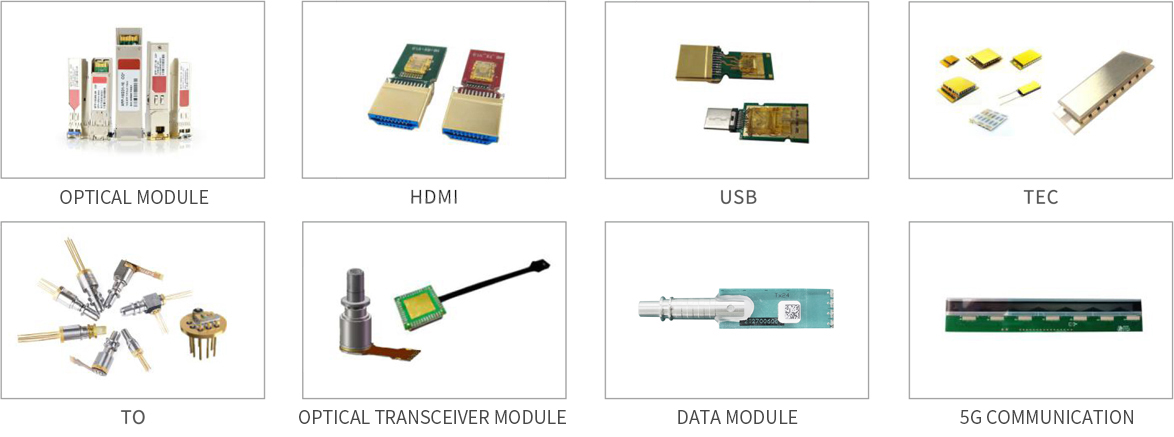

High Precision:

X/Y placement accuracy: ±3µm @3σ;

Theta placement accuracy: ±0.1°@3σ;

High speed:

COC placement cycle time ≤8s (Excluding temperature curve);

COB placement cycle time ≤3s (Depending on the material);

FC placement cycle time ≤8s (Depending on the material);

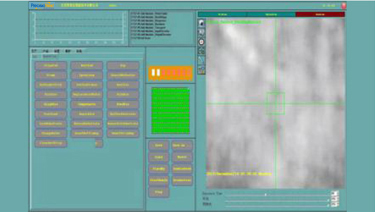

Supporting the placement of multiple wafers and AB Die of different sizes;

High automation, automatic loading and unloading transmission system, automatic glass sheet cyclic pick-and-place test function (BMC), etc.;

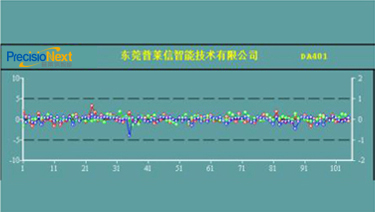

Providing high-precision and micro-motion PostBond data. No manual retest is needed after placement, which greatly reduces the labor cost.