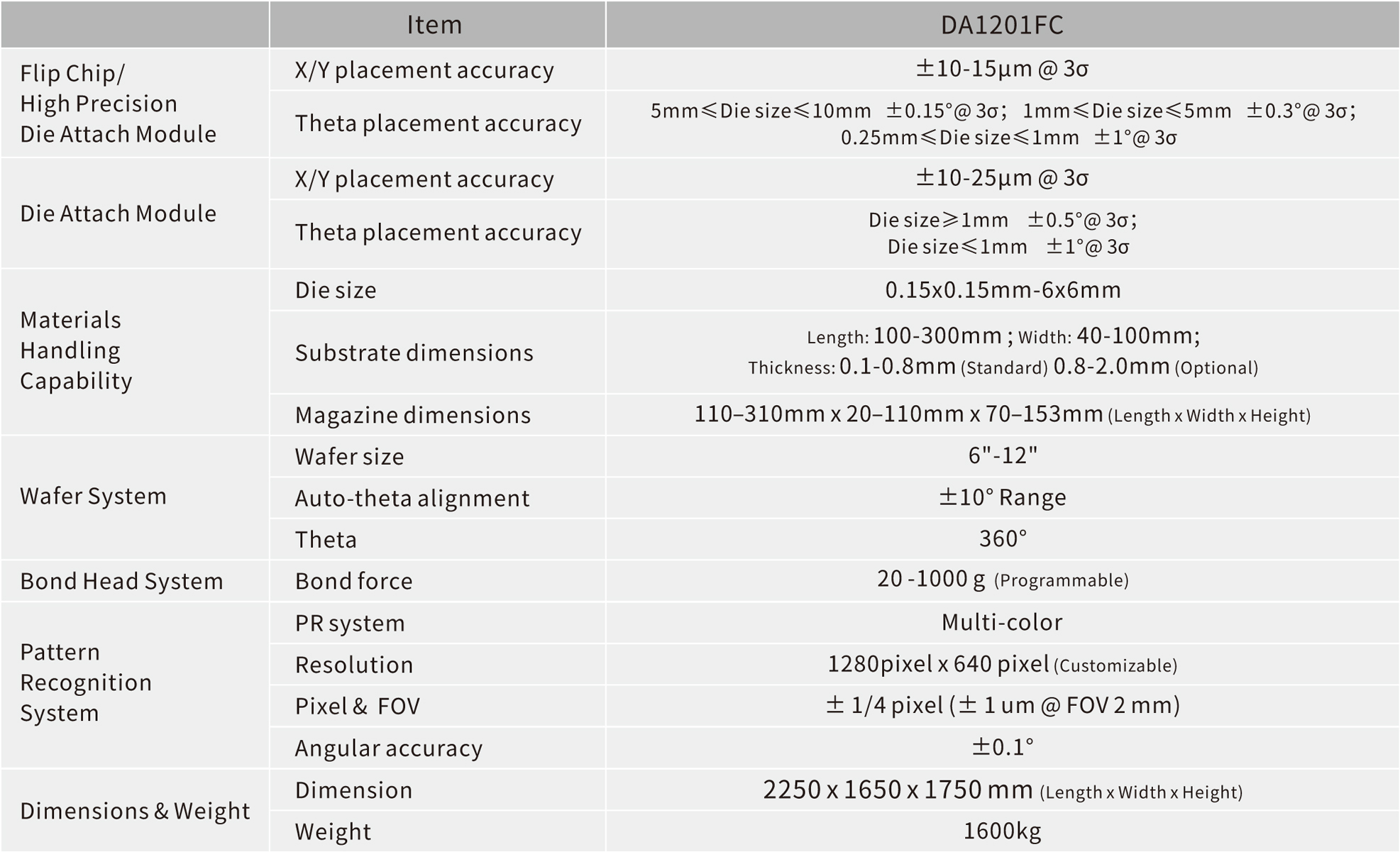

X/Y placement accuracy:

Flip-chip/high-precision die attach mode: ±10-15μm@3σ;

Die attach mode: ±10-25μm@3σ;

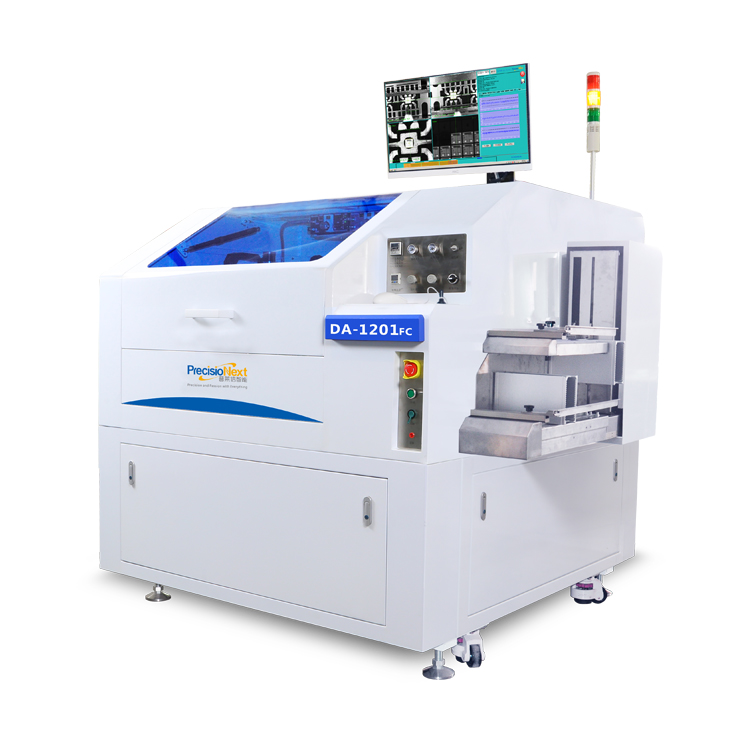

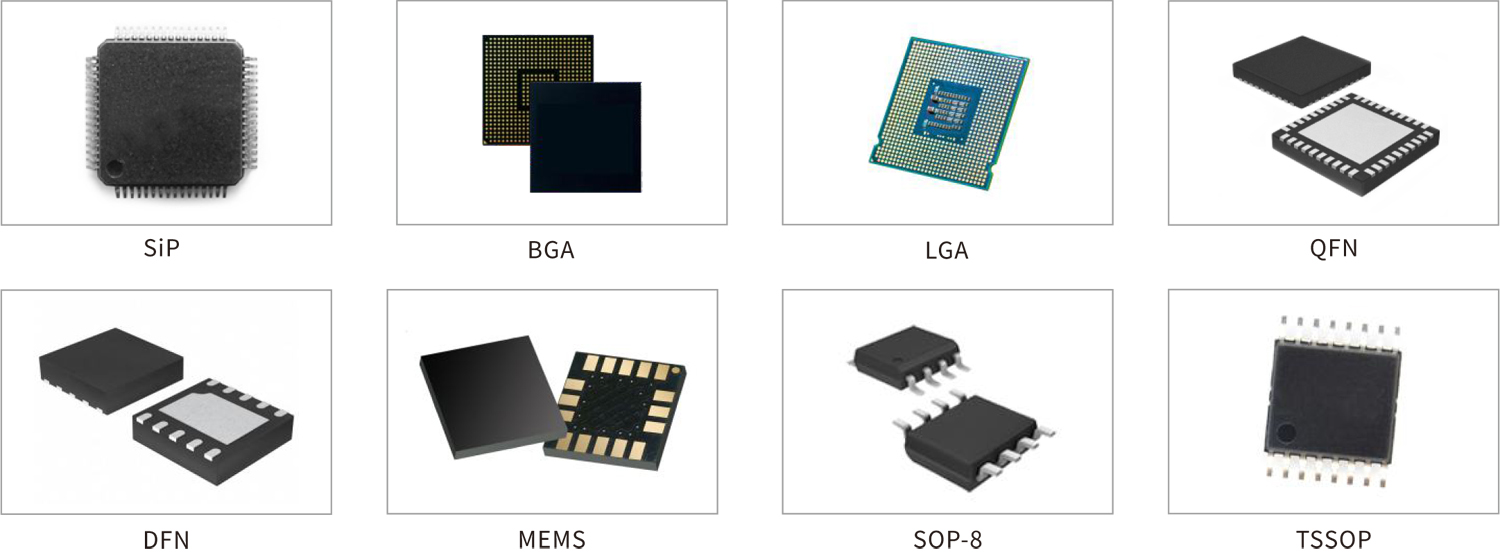

Specially designed for flip chip devices with low pin count, DA1201FC provides a fully automatic high-speed flip chip solution for various devices, such as SOIC, SO, QFN, BGA, LGA, etc. At the same time, it is equipped with die attach system;

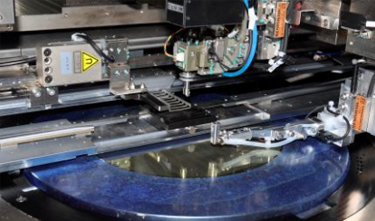

High-speed and high precision die bonding capability;

MS Windows® operating system and flexible connectivity;

Flip chip and die bonding in one machine - the conversion between the two processes is simple and easy;

Comprehensive inspection system;

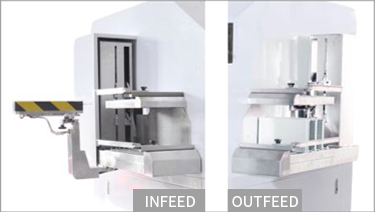

High density lead frame handling capability.