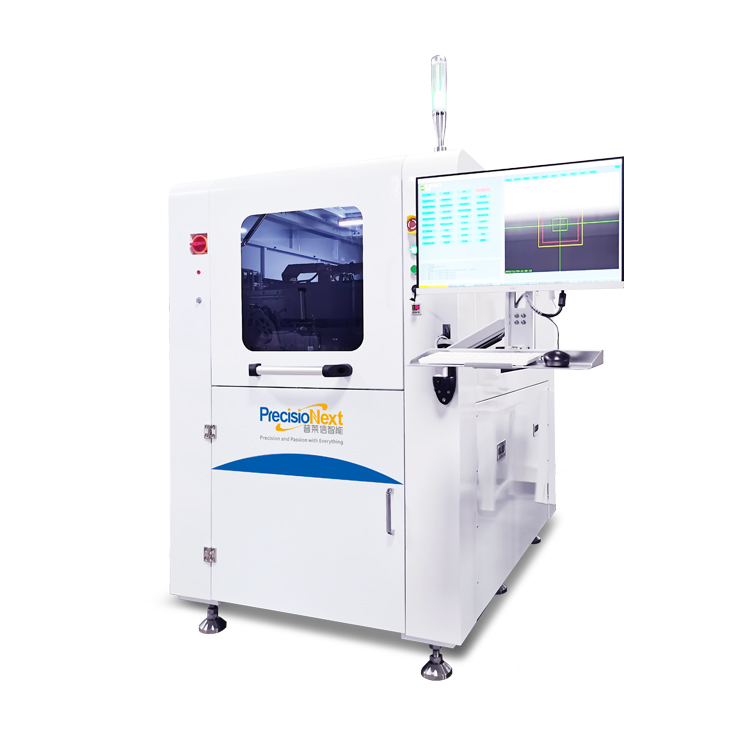

Exclusively used the flip chip COB needle based die attach process, suppport high-speed transfer of real MiniLED-level chips. The traditional Pick & Place mode does not support die size <200μm.

Ultra-high-speed, UPH(Unit Per Hour) can reach 360K, which is 10 times higher than the traditional Pick & Place mode.

The accuracy can be from 5 to 15 μm with high yields. Which can process chips 10 to 1500μm.

Applicable for mass transfer of FOPLP, backlight display and LED display. Support for large substrates 950x500mm.

No need mapping sorter process. Small footprint and low energy consumption.

Matured technology: A similar technology with Company A used for the mass-production of MiniLED backlight.