- Homepage

-

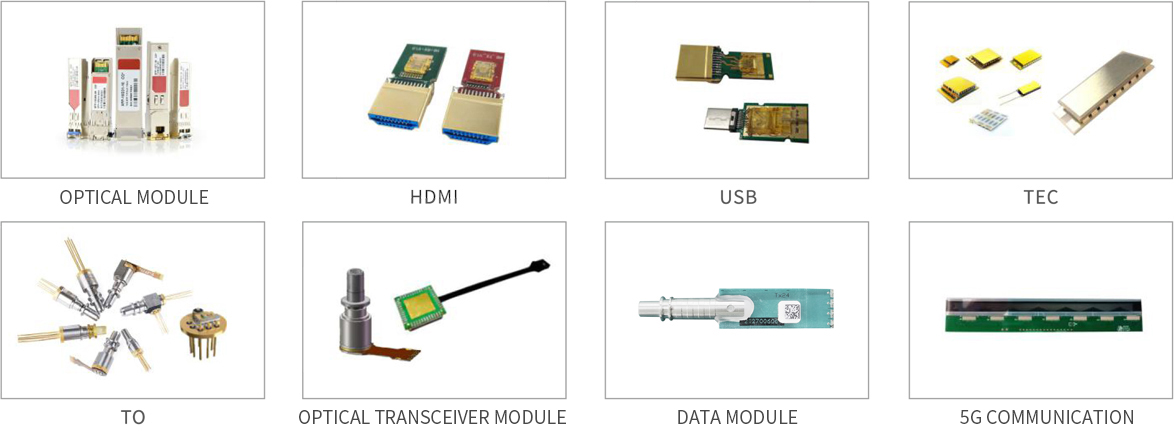

Products

-

DA1201 IC Linear High Precision Die Attach

DA1201FC Flip Chip and Die Attach

DA801 IC Linear High-speed Die Attach

Clip Bonder High-speed Clip Bonding System

-

Light 2300 Ultra-high Precision Die Attach

DA403 Multifunctional Ultra High Precision Die Attach

EU403 High Precision Eutectic Die Bonder

Lion 2300 Ultra-high Precision Die Attach

Lion 2600 Camera Module Attach

DA402 Ultra-high Precision Die Attach

DA401A Ultra-high Precision Die Attach

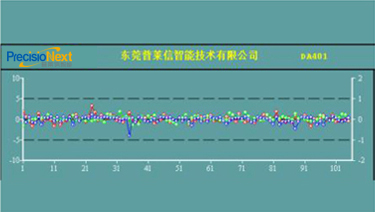

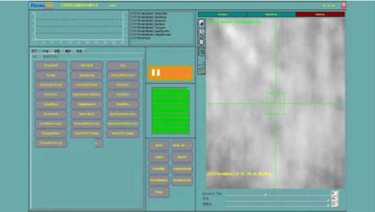

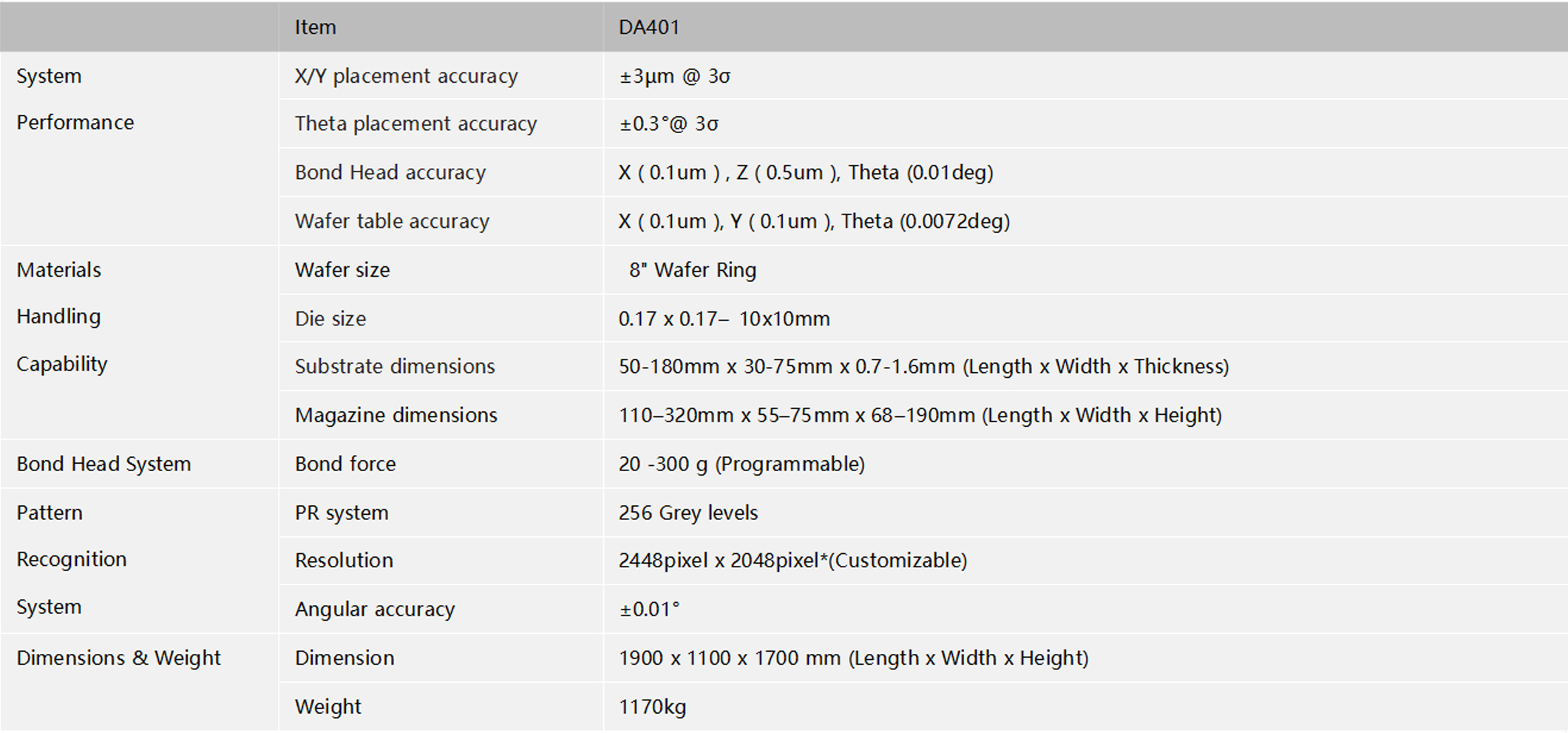

DA401 Ultra-high Precision Die Attach

Lens Bonder High Precision Lens Attach

- Solutions

- About Us

- News

- Contact Us

- Career