Semiconductor equipment company PrecisioNext has recently released a flip-chip COB mass transfer solution for MiniLED-the ultra-high-speed flip-chip bonding equipment XBonder product, breaking the technical bottleneck of the domestic MiniLED industry. More than 20 media outlets, including 36Kr, TMTPOST, PE daily, JRJ, and others, reported on this.

MiniLED refers to LED products with a die size of 50μm to 200μm, and is hailed as the next generation of display technology. Compared with OLED, MiniLED has a higher dynamic range, better contrast, and a wider range of operation than OLED. As Apple begins to use it in batches in its new generation of iPads and Mac computers, the Mini LED industry has become a hot spot in the entire display industry. Apple, TSMT, and K & S have adopted a flip-chip COB high-speed chip transfer solution that is completely different from the traditional pick-and-place in their Mini LED production line. The industry generally believes that flip-chip COB will be the decisive technology of the Mini LED industry from concept to commercial.

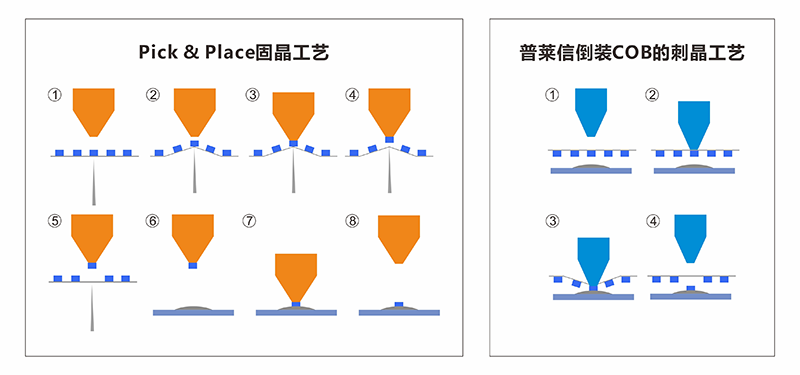

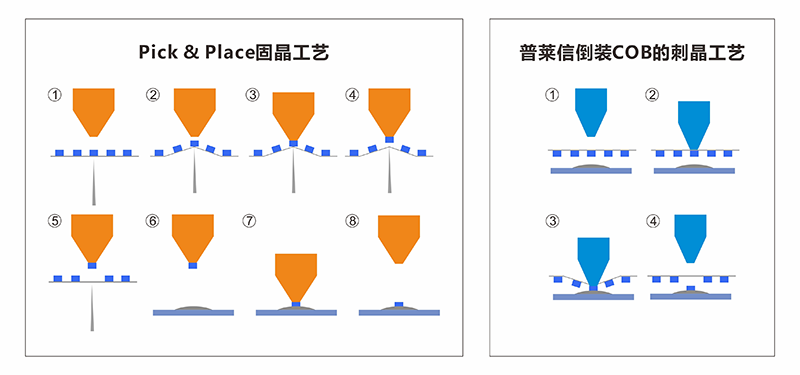

The traditional chip transfer technology adopts the Pick & Place method. Because the die size of MiniLED is less than 200μm, the aperture of the bond head cannot be within 200μm in the Pick & Place mode. In addition, MiniLED requires ultra-high speed. All the traditional chip transfer modes Neither the equipment nor the equipment can serve the mass production of Mini LED. Apple and K&S took a completely different route, using the flip-chip COB thorn die solution, completely abandoning the bond head, and greatly improving die transfer speed, becoming the first manufacturer in the world to mass-produce Mini LED products.

PrecisioNext started research on the thorn die process and equipment for flip-chip COB many years ago and has applied for related patents. At the same time, it has jointly developed and successfully launched XBonder with the Chinese Academy of Sciences and LED chip giants. The minimum die size supports 50μm, and the fastest per-hour production capacity can reach 180K, and the placement accuracy can reach ±15μm. The release of this device broke Apple and K&S's technological monopoly in this field and solved the technical bottleneck of the scale of the domestic Mini LED industry.Once the XBonder was released, it received wide attention from the display industry, Huawei, and LUXVISIONS Innovation (Taiwan LITEON), etc. to conduct in-depth technical exchanges with the company and start formal process cooperation. Many domestic display giants and packaging companies are also actively following up. It is believed that with the maturity of equipment and processes, Mini LEDs will usher in real mass in 2021. production and industrial explosion.

The Introduction of PrecisioNext CEO: PrecisioNext is a leading high-end equipment platform company in China. It has the underlying platform technologies, including motion control, linear motor, servo drive, and vision system, with completely independent intellectual property rights. Semiconductor equipment is the main product of PrecisioNext. Including the products of the 8-inch and 12-inch high-end IC die bonder series, some have reached the international advanced level, the high precision die bonder series, with placement accuracy of 3μm, specially designed for optical communication and other high-precision placement requirements. XBonder is an extension of PrecisioNext's MiniLED equipment.